High strength and performance with beauty and versatility. These are the characteristics of the laminated safety glass manufactured by GlassecViracon.

The laminated safety glass is composed of two or more plies joined by an interlayer, which prevents the glass from shattering if it breaks. This property reduces the risk of bodily injury and damage, and keeps any gaps closed.

Laminated glass is optimum for applications that require acoustic performance and safety at different levels. In addition, it offers greater protection against UV rays and wide aesthetic possibilities due to a wide variety of available colors and interlayer opacity.

The laminated safety glass processed by GlassecViracon meets the requirements of national (ABNT NBR) and international (ANSI, ASTM and EN) standards.

Available Configurations

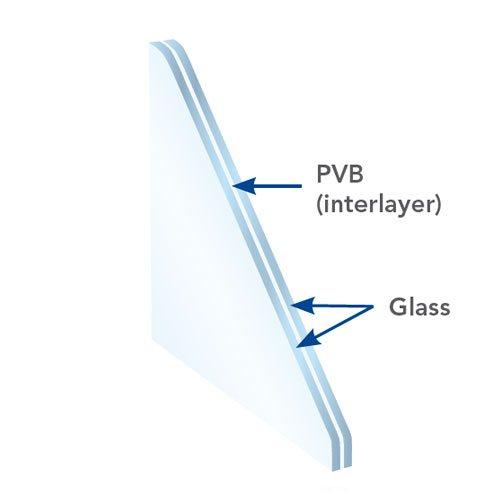

Laminated Safety Glass

The laminated safety glass is composed of two plies of glass joined by PVB or SentryGlas (SGP) and is widely used in facades and railings.

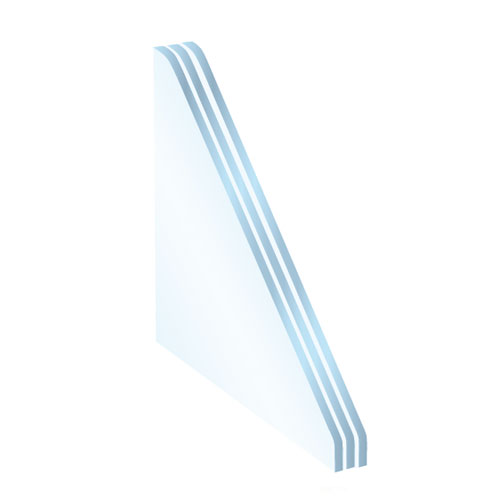

Multilaminated Glass

Multilaminated glass is manufactured with more than two glass plies joined by interlayers, which provides the product with high level of safety.

It is also known for protection against vandalism, used in places that require greater protection, such as banks, shop windows and guardhouses.

Components

Interlayer

Interlayer permanently joins glass plies. It is a key component for the safety, UV protection and thermoacoustic performance of the laminated unit.

GlassecViracon offers several interlayer options supplied by world-class vendors that will meet your specification requirements.

GlassecViracon uses objective nomenclature to identify each of its products, classified into five categories:

• Product name;

• Type;

• Aspect;

• Thickness;

• Code — GA for Standard products;

• Code — GV for Prime (select) products;

• Code — GL for customized products.

This helps you easily select the product you want to specify, with the respective performance details.

Example of product commercial description.

| INSULATING | SOLAR CONTROL | BLUE | 26 MM | GA 120 |

|---|---|---|---|---|

| Product | Type | Appearance | Thickness | Product Code |

Energy Performance Details

The details below are available for all of our products.

| TL | Light Transmittance |

| RLe | External Light Reflectance |

| RLi | Internal Light Reflectance |

| TE | Energy Transmittance |

| RE | Energy Reflectance |

| Abs | Solar Energy Absorptance |

| FS | Solar Factor |

| CS | Shading Coefficient |

| Valor U | U Value |

| IS | Selectivity Index |

Glass Specification

You can specify architectural glass according to appearance and performance criteria.

On our website, by clicking Search Product, select the information in the following

fields:

• Product: insulating, laminated or monolithic glass.

• Type: colorless, colored or solar control.

• Silk Screen: yes or not.

• Appearance: amber, blue, greenish blue, white, bronze, champagne, gray,

bluish gray, extra light, colorless, neutral, bluish neutral, extra light neutral,

opaque, silver and green.

• Performance: specify TL (light transmittance) and FS (solar factor).

Quality permeates all of GlassecViracon’s processes.

The excellence of our products and services is part of our brand, recognized by our customers in Brazil and overseas.

We are a sound, responsible company with 30 years’ experience, and we meet all domestic and international standards and requirements, such as traceability of all products, from arrival of the raw material at our manufacturing facilities to installation.

All inputs used in the processing of our products are approved by the raw material manufacturers and undergo rigorous control systems in our Quality Laboratory.

Certifications

ISO 9001

In 2002, GlassecViracon was awarded its first ISO 9001 certification, and underwent recertification auditing in 2009, 2014 and 2020.

ISO 9001 covers all of our operations — from planning, procurement, manufacturing, shipping, sales, customer service and office services — to ensure high quality in our services and products.

IGCC

Certified by AMS, Inc. under the Insulating Glass Certification Council program, which ensures the life of GlassecViracon’s insulating glass through periodic plant audits and rigorous tests carried out in international laboratories.

SGCC

Certified by AMS, Inc. under the Safety Glazing Certification Council program , which certifies the safety and quality of GlassecViracon’s laminated safety glass through periodic plant audits and rigorous tests carried out in international laboratories.

MDCA

Approved by interlayer suppliers under the Miami-Dade County Department of Regulatory & Economic Resources program, which qualifies our company to supply laminated safety glass to regions affected to hurricanes, such as Florida, United States, and regions of Central America and the Caribbean, among others.

Laboratory

We are the only company in Brazil that owns a Quality Laboratory where tests are carried out to guarantee the color and shade homogeneity of our glass.

All batches of raw materials undergo spectrophotometric tests, in addition to specific tests according to the product’s characteristics.

Control systems for laminated glass:

• Normative Tests – Quality tests that ensure that the laminated glass meets product safety requirements (Baked Test, Boil Test, Impact Test, Ball Drop, Moisture Test with and without condensation).

• Pummel Adhesion Test – Test to detect the level of adhesion between the interlayer of the laminated glass.

Control systems for heat-strengthened glass and tempered glass:

• iLook – High-precision scanner to ensure planimetry and optical quality.

• Heat Soak Test (HST) – Thermal test to reduce the risk of spontaneous breakage of tempered glass by detecting the presence of nickel sulfide in the substrate.

• Normative Tests – Quality tests that ensure that the tempered glass meets product safety requirements.

GlassecViracon also has a vertical machining center to process extra-large size glass with high precision and quality in holes, cuts and finishing.

Technical Standards

| NBR 7199:2016 | Glass projects, execution and applications in construction. |

| NBR 14698:2001 | Tempered Glass. |

| NBR 14697:2001 | Laminated Glass. |

| NBR 16023:2011 | Coated solar control glass — Requirements, classification and test methods. |

| NBR 16015:2012 | Coated solar control glass — Processing and handling requirements. |

| NBR 16673:2018 | Insulating glass – Features, requirements and test methods. |

| NBR 16918:2020 | Heat-strengthened glass. |

Trademarks

Glassec® is a GlassecViracon trademark.

GV Prime® is GlassecViracon’s trademark of select products.

Insulatto® is a GlassecViracon’s double insulated glass line trademark.

GlassecViracon® is a GlassecViracon trademark.